|

颗粒饲料品质包括硬度、粉率、耐磨度及质感,而影响品质因素包括有原料特性、机械设计、制造技术、温度、铸膜材质、厚度、压辊间隙及其他等因素,而其中对配方人员最重要的便是原料特性,如原料水分、物性、成分等均影响颗粒本质,我们甚至可将各种原料对品质影响分成不同等级,在计算配方时将之列入成分之一,然而在配方变更时,我们可以预估颗粒料本质状况,随之改变操作条件。在列出各种原料对颗粒料品质影响之前,我们先熟悉一下不同成分及性状对颗粒料品质影响状况,那么我们才容易对各种原料制粒特性原因有个概略了解。

一、原料成分、性状对颗粒料品质之影响

1. 蛋白质:豆粉等植物性油粕类、动物胶及其他低脂蛋白质原料,加热后可曾粘,故有助于制粒,对与颗粒料品质具有正面效果。

2. 粗纤维:纤维本身并无粘着性,但含纤维多的原料比较轻,通过铸模的时间较长,故颗粒料较硬,但对机械磨损较大,生产效率较差。

3. 粗灰分:包括矿物质、沙石等,此类物质磨擦大,不利成形,亦损耗铸模,减低其寿命,且降低生产效率。

4. 油脂:原料或饲料脂肪包括天然存在及人工添加的,任何来源地脂肪均能增加制粒的生产效率,但脂肪含量太高时,会严重影响成粒品质。油脂具润滑效果,保护铸模,并提高生产效率。

5. 淀粉:淀粉经蒸汽加热即糊化,具粘性助粘着力,尤其麦类淀粉助粘效果更高,但蒸汽不足或颗粒太粗则效果减低。

6.热易变性物质:脱脂奶粉、乳清粉、蔗糖、葡萄糖等经蒸煮后,粘性变高,有助硬度,但此类物质加热过渡时,容易焦化,太粘反堵塞铸模小孔,故蒸汽量应减少,配方许可下,加少许油脂可避免热变性。

7. 水分:水具润滑,助糊化效果。

8. 比重:饲料密度高时,制粒效果较佳。

9. 细度:较细的原料,或制粒前将原料磨得细些可提高制粒效率,改善硬度,增加粒料密度,延长铸模寿命,其原因是较细的粉料,能使蒸汽充分渗入至每一颗粒中心,使之变得较柔软而具可塑性。

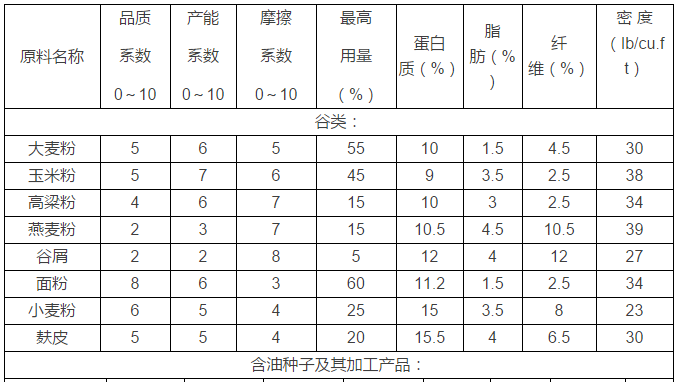

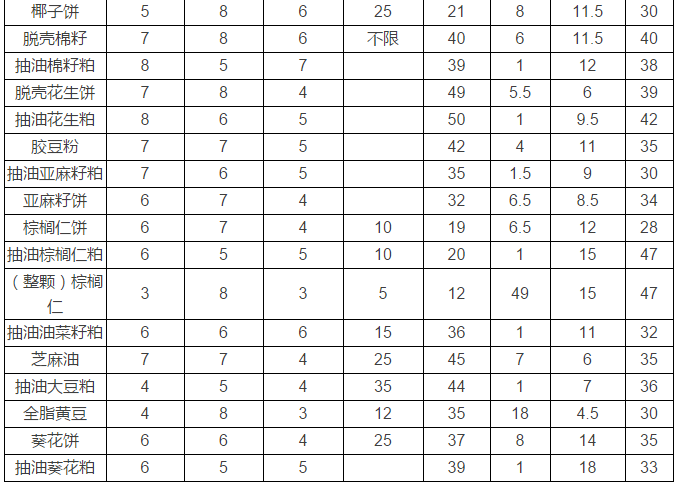

二、饲料原料制粒特性

我们在应用饲料原料时,若能事先知道原料的营养成分及物理性质,并能预测其物理特性对制粒的影响时,对原料的使用必然更得心应手。将各种原料的物理性质与营养值分析之后,制成表,在表中除了可供输入电脑,计算配方的营养值外,还列了三条重要的物理值,依其营养的大小,分别以0~10间的数字表示。这三项物理值是:

各种饲料原料制粒特性

一、 品质系数:即原料对成粒品质的贡献度,此项因素数值愈高,表示用该原料制造出来的粒料品质愈好。 一、 品质系数:即原料对成粒品质的贡献度,此项因素数值愈高,表示用该原料制造出来的粒料品质愈好。

二、 产能系数:即该原料对粒料产出量的影响。此一因素愈高,使用该原料的生产能力愈高。

三、 摩擦系数:即该原料对铸模寿命的影响,此一数值愈高,该原料对铸模的磨损愈厉害。

表中的这些数据完全基于经验,并经过许多同业朋友的证实,希望这些数据对您有所助益。应用此表时,应注意以下事项:

1.三项物理因素的设定,使实际上所利用的原料皆能落于0到10之间。

2. 原料混合后,其特性很难预测(合成效应),这也是由表中计算值预测的成粒品质与实际所生产粒料品质有所差异的原因。

3.表中数据是根据平均样本得来的,饲料原料系天然产物,每一批都会有所变异,因此当同一配方下得到不同品质的粒料,而操作条件不变,则一定是配方中的某一种原料有很大变异。

4. 事实上,如果您对表中所列数字有所不同看法时,我们也不会感到惊奇。不同的工厂使用同一原料与同一工厂使用不同的原料,其成粒品质必然有异,因没有所谓标准的饲料厂,故同一原料在不同的工厂其效果有所差异,也就不值得大惊小怪。切记!表中的数值是平均值。谈到原料特性与营养值,须知其中所含变化错综复杂,此乃为什么先前一直无人数字来表示原料特性的原因。

5.表中有一栏原料最大使用量的限制,其着眼点全然在生产上考虑,若考虑经济上的理由,或营养上的观点,或是有关的规定,则在使用量上必会有很大的区别,配方使用上尽可突破表中所述之限量。同时切忌配方的设计是以最经济的方法组合原料来供给动物所需的营养,而不要造成生产上的困扰!原料成本约占饲料价格85%,此一成本超过制造成本甚多,约15至20倍,这也是为什么为了生产上的困难而更改配方时,会导致总成本大增的理由。所以一般在生产上尽量不要为了制造上的困难而更改配方,制造上的困难要以较经济的手法来克服,逼不得已才改变所用原料。

The English version

Grain quality including hardness, powder feed rate, the wear-resisting degree and texture, and the factors affecting quality consists of material characteristics, mechanical design, manufacturing technology, casting temperature, membrane material, thickness, and other factors, such as roller clearance of which is the most important raw material for formulation personnel features, such as the moisture, physical properties and composition of raw material affect the nature of particles, we even impact on the quality of all kinds of raw materials can be divided into different levels, when calculating the formula will be listed in the ingredient, however in the recipe changes, we can forecast grain nature condition, change the operating conditions. Before listed effect on grain quality of different materials, we first familiarize yourself with the different components and effects on grain quality, so we are easy to granulating features cause all kinds of raw materials has a general understanding.

One, the effects of raw material composition, properties of grain quality

1. The protein flour plant oil, such as meal, animal glue and other low lipoprotein quality raw materials, ever stick after heating, it helps to granulating, with grain quality has a positive effect.

2. Crude fibre: fibre itself and no tackiness, but fiber raw material is lighter, more through the mold for a long time, so the grain is hard, but the mechanical wear, low production efficiency.

3. Crude ash: including minerals, sand, etc., such friction material is big, bad shape, mold also loss and reduce its life, and reduce the production efficiency.

4. Grease: raw material or feed fats include natural and artificial added, any source of fat can increase the production efficiency granulating, but fat is too high, will seriously affect the quality of granulating. Grease lubrication effect, protect the mold and improve production efficiency.

5. Starch, starch by steam heating the gelatinization, viscous help adhesion, particularly of wheat and barley starch adhesion effect is higher, but the lack of steam or particles is too thick, reduce effect.

6. The heat variability material: skim milk powder, whey powder, sucrose, glucose and so on after cooking, high viscosity, hardness, but this kind of material heat transfer, easy to coking, too stick anti clogging mold holes, so the steam should be reduced, recipe permission, add some oil to avoid thermal denaturation.

7. Water: water lubrication, gelatinization effect.

8: the proportion of feed density high, granulating effect is better.

9. Fineness: thinner raw materials, grinding materials or granulating will have to fine some granulating efficiency can be improved, to improve the hardness, increase the aggregate density, extend the life of the mold, the reason is that the fine powder, can make steam fully penetrate to each particle center, make it become more soft and plasticity.

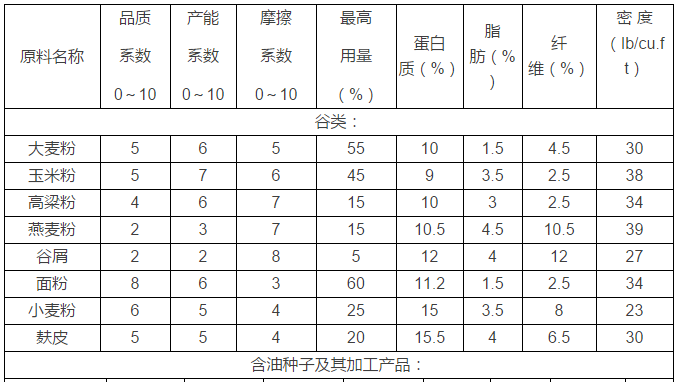

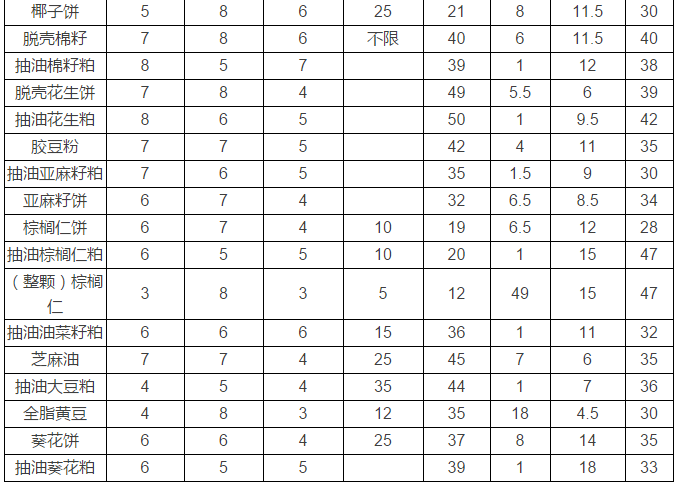

Second, the feed raw material granulating

When we are in the application of feed raw materials, if can know in advance the nutritional composition and physical properties of raw material, and can predict the physical properties of granulating, the influence of the use of raw materials will be more handy. The physical properties of various materials and nutrition value analysis, make table, in the table in addition to input computer, calculation formula of the nutritional value, also listed the three important physical values, according to the size of his nutrition, expressed as a number between 0 ~ 10 respectively. The three physical values are:

A variety of feed ingredients granulating features

One, the quality factor: the contribution of granulating quality raw materials, the higher the value, the factors said produced with the raw materials of aggregate quality is better.

Second, the capacity factor: the raw material's impact on aggregate output. This factors, and the use of the raw materials of production capacity.

3, friction coefficient, namely the influence of the raw material to mold life, this value is higher, the raw material of mold wear the more severe.

These data in the table is completely based on the experience, and confirmed by many peer friends, hope these data will help to you. Application of this table, we should pay attention to the following items:

1. The three set of physical factors, so that actually use the raw material can fall between 0 to 10.

2. After mixing raw materials, its characteristics is difficult to predict (effect), which is calculated by the table values predicted granulating quality and actual aggregate produced quality differences.

3. The sample data in the table is based on the average, feed raw materials is a natural product, each batch will vary, so when the same formulation under different quality of aggregate, and operating conditions the same, is must be a kind of material in the formula has great variation.

4. In fact, if you are looking for different Numbers listed in the table view, we wouldn't be surprised. Different factories use the same raw materials with the same factory use different raw materials, its quality must be different, because there is no standard feed mills, and the effect for the same material in different factories, also is not surprising. Remember that! The value in table is average. When it comes to raw material characteristics and nutritional value, information containing complex change, this is why the previous has been no one number to represent the material characteristics.

5. There is a column in the table's largest raw material usage limit, its focus completely on the production, if consider economic reasons, or nutritional point of view, or the relevant provisions, in there will be big difference on the usage, formula can use breakthrough the limit of described in the table. At the same time the formula design of avoid by all means is the most economical method combination raw material to supply for animal nutrition, and don't cause trouble production! Raw material cost accounts for about 85% of feed price, the cost more than the manufacturing cost very much, about 15 to 20 times, which is why change the formula for production difficulties, can lead to increased the cost of the reasons. Commonly so try not to create difficulties in production and change the formula, manufacturing difficulties for the economy to overcome, forced to change materials.

|